Portfolio

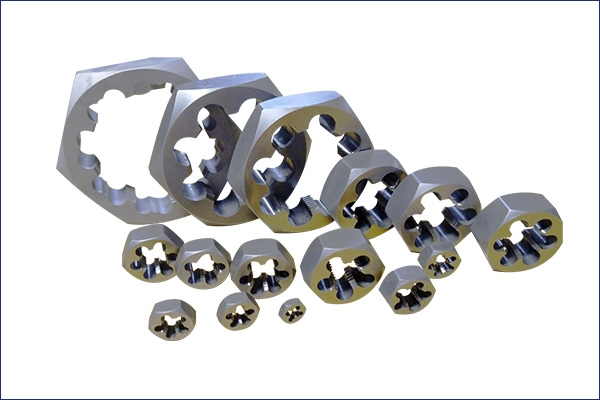

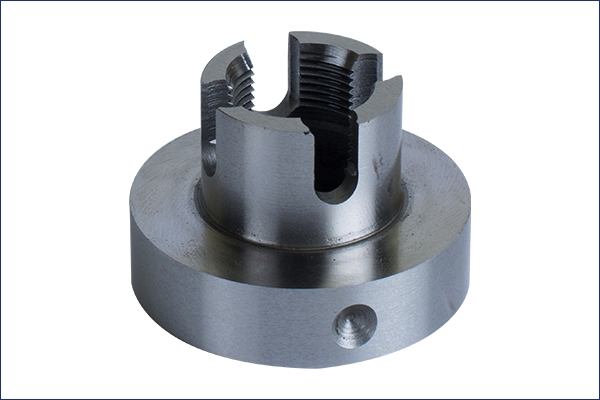

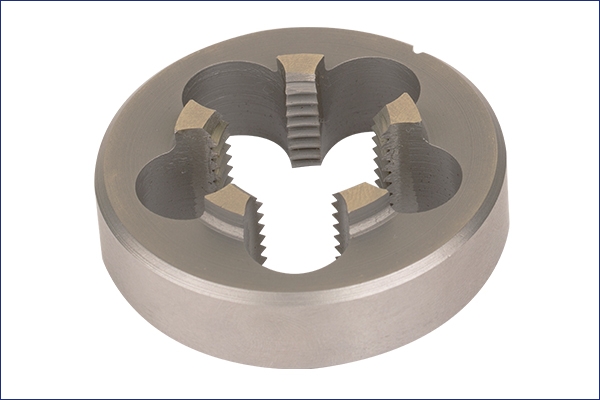

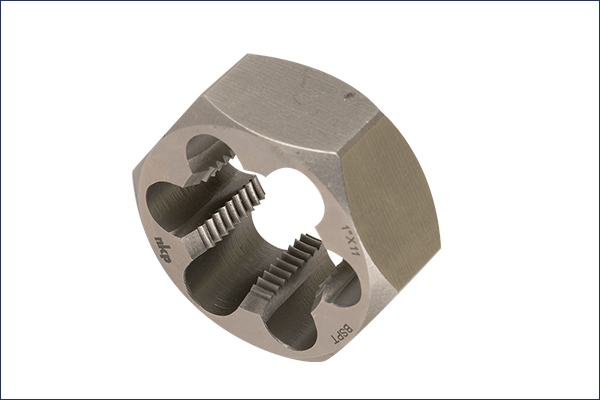

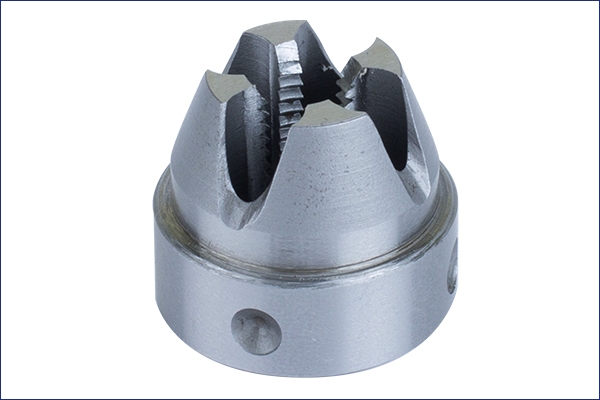

Nikopas offers a wide range of products, including ‘HEX DIE-NUTS’/ ‘THREADING DIE NUTS ’, ‘ROUND THREAD CUTTING DIES’, nkp. marketed under the brand name of . Our manufacturing processes employ the latest tools, techniques and technology, so as to consistently roll out high quality output which meets industry standards.

The ‘nkp’ products have been very well accepted by our customers within India and abroad due to their exclusive features like dimensional accuracy, thread finish on die as well as on final product, cutting efficiency and tool. Precision has always been the hallmark of the ‘nkp’ products, It is rightly said about Nikopas nkp “OBSESSED WITH PRECISION”.

HOW TO GET BEST OUT OF YOUR nkp DIES

Thread Cutting Dies & Rethreading Hex Die Nuts

As a rule, dies are manufactured solid, pre slotted (Form B). The dies produce male threads within the tolerance zone 6g or medium fit. The narrow web (Slot) on the Die can be easily cut off, when special tolerance required. The Die will then be adjustable (Form A).

Generally two types of dies commonly used viz., Cut Thread Dies and Ground Thread Dies. Ground Thread Dies have thread lapped and produce good quality threads. They are more accurate and generally used on machines. Cut Thread Dies are used by hand.

Round Dies are used to produce threads whereas Hexagonal Die-nuts or Rethreading Hex Die-nuts are used for repairing of damaged or worn out threads. A simple spanner is used to drive the Hex Die-nuts.

nkp (LAPPED) Dies are ground after hardening in exact concentricity to their threads in both the perpendicular and horizontal planes. In good working conditions the Dies will always run true on the workpiece.

nkp (LAPPED) Dies produce exceptionally good finish.

The design and heat treatment of dies give a high efficiency in steel up to 750 N/mm2. For steel with tensile strength 750 N/mm2and shot chipping brass special types Dies are available.

The number of flutes in the Dies depends on the nominal size of threads and on the application.

The High Speed Steels and special Carbon Steels used for manufacturing of Dies are subject to a strict quality inspection.

nkp (LAPPED) Dies produce exceptionally good finish.

The design and heat treatment of dies give a high efficiency in steel up to 750 N/mm2. For steel with tensile strength 750 N/mm2and shot chipping brass special types Dies are available.

The number of flutes in the Dies depends on the nominal size of threads and on the application.

The High Speed Steels and special Carbon Steels used for manufacturing of Dies are subject to a strict quality inspection.

The carefully supervised heat treatment produces quality and highly efficient tool life.

The quality and accuracy In size of thread produced depends essentially on many factors such as machines should be in A1 condition preferably with positive feed and chuck having axial and radial compensation. They prevent defective threads. Special attention must be paid to perfect alignment of the work pieces.

True alignment of work piece and Die are of prime importance.

Dies must be sharpened correctly and in due time. Blunt or faulty re-sharpened tools produce defective threads and increase torque up to 100%, causes excessive wear and breakage.

While producing male threads with Dies it should be noted that the diameter of the bolts / component must always be a little smaller than the nominal size of the threads. While producing ISO male threads within the tolerance position 6g or medium, the negative allowance for the major diameter must be considered (MAJOR DIAMETER OF BOLTS = NOMINAL SIZE MINUS ALLOWANCE).

In principle diameter of bolt should be as low as tolerance will allow.

In order to facilitate start of threading, the bolt should be provided with bevel / chamfer.

A perfect alignment of the tools axis to the work piece is very important to produce male threads and good Die life.